Oil Tech Services, Inc.

- 800 Wilcrest, Suite 101

- Houston, TX 77042

- 281-456-9023 (plant)

- 713-789-5144

- sales@oiltechservicesinc.com

Since 1995, Oil Tech Services, Inc. has engineered and manufactured Multilayered High Vacuum Gettered Insulated Tubing (VIT) for heavy oil recovery (thermal enhanced oil recovery) and geothermal well completion.

Our mission is to be a reliable source of Vacuum Insulated Tubing, progressively improving the technology, performance, and reliability. Our manufacturing is in Houston Texas. We provide the high quality Vacuum Insulated Tubulars enabling injection of high quality steam into deep heavy oil bearing zones and production of reservoir heated fluids for geothermal recirculation projects. Strings can be customized for size, thermal performance, and thread connection system.

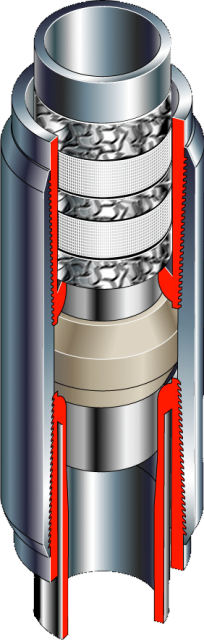

Thermal Tube 3-H (High Vacuum, Getter™ maintained)

For Maximum Insulating Capacity at High Temperatures up to 670°F, and depths to 5000 feet.

- Thermal Protection of Well Casing

- Limits Well Bore Heat Loss

- Delivers high Quality Steam to oil producing zone for thermal enhanced oil recovery

- Reduced heat loss and improved thermal efficiency for geothermal energy production (EGS)

- Available with Premium Threaded & Coupled Connection

- Available with Integral Premium Connection on Inner Pipe

- Insulated Connections

- 20 to 30 Plus Run/Pull Cycles

- Produced from API Oil Field Tubulars

- Extended Life: 10 Years Plus of Continuous Service

- Available in Chrome Alloy Steel OCTG’s

Thermal Tube 2-H (Argon Gas Backfilled)

For Intermediate Insulating Capacity at High Temperatures up to 670°F.

Thermal Tube 2-H is an Argon gas backfilled tubular product. Mechanically it is the same as the higher performance 3-H (High Vacuum, Getter tubing)

Multilayered High Vacuum, Gettered, Pre-Stressed Insulated Tubulars with Maximum

Insulating Capacity for High Temperature Applications up to 670° F

- Range 2 (Nominal 31.5 feet to 33.0 feet)

- API, 5CT Tubulars and Couplings

- Modified Buttress Couplings and Integral Connections

- Premium Connections Available

3-1/2″ x 2-3/8″ Others Upon Request

4-1/2″ x 2-7/8″

4-1/2″ x 3-1/2″

5-1/2” x 4-1/2”

Typical Specifications

| Physical Data | 3.50 x 2.375 | 4.50 x 2.875 | 4.50 x 3.50 | 5.50 x 4.50 | |

| Total Weight (#/ft) | 14.5 | 18.5 | 21.5 | 28.5 |

Outer Casing

| -O.D. (in.) | 3.50 | 4.50 | 4.50 | 5.50 | |

| –Wall Thickness (in.) | 0.254 | 0.250 | 0.250 | 0.275 | |

| –I.D. (in.) | 2.992 | 4.000 | 4.000 | 4.950 | |

| –Weight (#/ft.) | 9.50 | 11.60 | 11.60 | 15.50 |

Inner Tubular

|

–O.D. (in.) |

|

2.375 |

2.875 |

3.500 |

4.500 |

|

–Wall Thickness (in.) |

|

0.190 |

0.217 |

0.254 |

0.271 |

|

–I.D. (in.) |

|

1.995 |

2.441 |

2.992 |

3.958 |

|

–Weight (#/ft.) |

|

4.50 |

6.50 |

9.50 |

12.75 |

Operational Data – Vacuum System with Getter

|

Nominal Conductivity |

Typical Application |

||||||||||||||||

|

|||||||||||||||||

Operation Data – Argon Gas Backfilled

|

Nominal Conductivity |

Typical Application |

||||||||||||||||

|

|||||||||||||||||

Sizes Available: Because of the lower efficiency of the Argon Gas insulation a large diameter insulated annulus space is required. The 4-1/2” outer tube will have a 2-7/8” (maximum) inner tube and the 5-1/2” outer tube will have a 3-1/2” (maximum) inner tube.